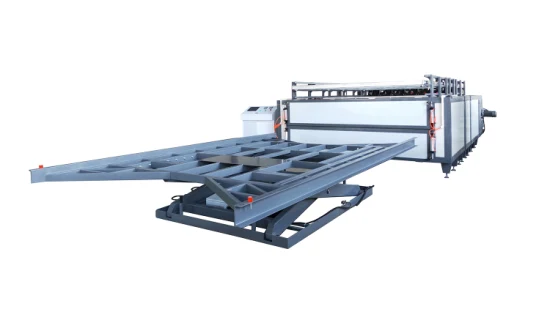

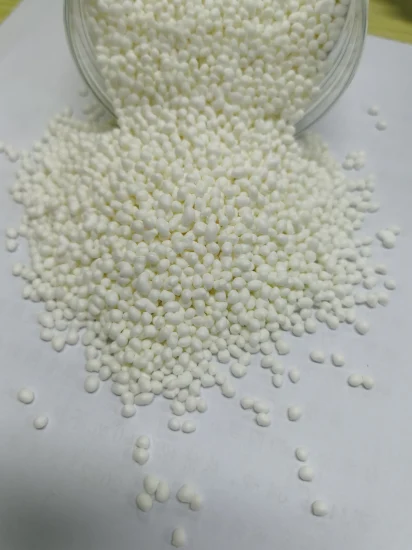

Plastic PE/PP/HDPE/LDPE/LLDPE/BOPP Film/Bag/Woven Bag/Non Woven/Fiber/Granulating Plant/Granulation Line/Agglomeration Recycling/Compact Pelletizing Machine

Basic Info

| Model NO. | BXC2 |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Electromagnetic Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008 |

| Condition | New |

| Machinery Test Report | Provide |

| Cutting Type | Water Ring Cut |

| Screw Diameter | 100/120/150/180/200 |

| Product Name | Compact Pelletizing Machine |

| Material | PP PE Soft Material |

| Cutting Way | Die Face Cutting |

| Screw Speed (Rpm) | 18 - 180 Rpm |

| Marketing Type | New Product 2023 |

| Warranty of Core Components | 1 Year |

| Gearbox | Guomao |

| Transport Package | Film Packing |

| Specification | 18*6.5*4.5 |

| Trademark | Boxin |

| Origin | Jiangsu |

| HS Code | 8477800000 |

| Production Capacity | 1000kg/H |

Packaging & Delivery

Package size per unit product 850.00cm * 500.00cm * 500.00cm Gross weight per unit product 3000.000kgProduct Description

Product Deacription

BXC series pelletizing production line integrates crushing compactor and pelletizing ,with high level of automation.With high feeding efficiency , it is more suitable for large size film to enter the equipment directly without crushing . Intelligent modular system and onekey for startup and shutdown are secure and stable . We can provide single stage , double stages and multi-stage structure according to different requirements in order to ensure the excellent quality of the particles. Specification| Model | BXC2-85/100 | BXC2-100/100 | BXC2-130/130 | BXC2-160/160 | BXC2-180/180 |

| Output(KG/H) | 150-200 | 250-350 | 450-550 | 650-750 | 800-1000 |

| Installed power | 140 | 205 | 290 | 410 | 580 |

| Labor requirements | 2-3 | 2-3 | 2-3 | 3-4 | 4-5 |

| Factpry area(L*W*H) | 10*5*4 | 12*5.5*4 | 14*6.5*4 | 16*6.5*4 | 18*6.5*4.5 |

Quality Control(Plastic Extruder pelletizing machine)· We have technical, engineer team design the sample machinery before enter into market· Production QC team ensure the machine manufacturing quality· We will running every machine after finished before shipment· Optional choose by client running the machinery by material Service System( noodle making machine )· Pre-sale: We given client the details technician offer, sign the sales contract etc. · In-sales: We supply the details layout, installation instruction, technician support for the clients; · After sales: We arrange engineer to install the machinery and training the workers for client; · We have 24hours team to solve the after sales problem; · We have free spare parts with the machine; · We supply long term spare parts for every customer· We always up date the new technology to every customerPackage and Loading

Certificates

FAQ

YOU MIGHT INSTERESTED IN FOLLOWING QUESTIONS

1. Are you manufacturer or trading company?

We are a professional recycling machines manufacturer for more than 15years we supplying full technical support and solutions, timely and professional service, always effort on quality, honest, win-win business for every client.

2. How do you assistant to install the machine on worksite?

We are experienced on turn-key project, engineer and technicians will assistant client on construction, installation, commissioning.

3. How can I get spare parts for replacement in other countries?

Wearing parts like blades, it is necessary to buy with machine, other parts in stock could be delivery out by express if urgent or by sea within 5days.

4. Can I use mark machine with different LOGO and color?

Yes, please confirm details with sales.

5. Can your customers test the machines?

Before buying and after production before leaving factory, we test machine you interested or paid with specified materials, free of charge.Feel free to contact us at any time!