TPU Film 20kHz Ultrasonic Sewing Machine with Rotary Horn

Basic Info

| Model NO. | RPS-RS20 |

| After-sales Service | Online Service |

| Warranty | 1year |

| Condition | New |

| Certification | CE |

| Application Place | Factory |

| Applicable Thickness | Middle Thickness Material |

| Drive | Foot Step |

| Name | Ultrasonic Sealing Machine |

| Frequency | 20kHz |

| Power | 800W |

| Generator | Digital Generator |

| Horn Material | Steel Horn |

| Weight | 150kg |

| Transport Package | Wooden |

| Trademark | Rps-sonic |

| Origin | China |

| HS Code | 8515900090 |

| Production Capacity | 200PCS/Month |

Product Description

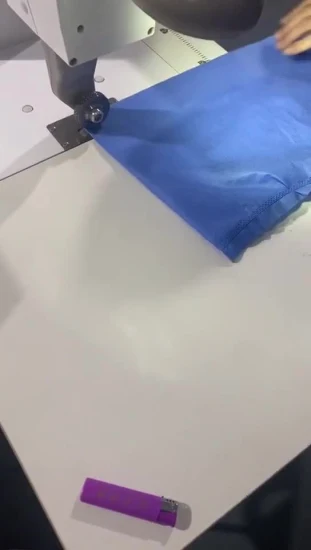

TPU Film 20 Khz Ultrasonic Sewing Machine With Rotary Horn

| Product name: | Ultrasonic lace machine |

| Product model: | RPS-R20 |

| Input power: | 1500-2500W(can adjustable) |

| Output frequency | 20KHZ |

| Running speed | 0-20m/min |

| Pattern size | Width:0-200mm;Diameter:50-75mm |

| Net weight | 120KG |

| Size (L * W * H) | 1200*600*1200 |

| Working power supply | 220V±5V 50/60HZ 6A |

The high-frequency oscillation is used to transmit sound waves from the welding head to the welding surface of the work object, and the molecules of the work object are instantly rubbed to reach the melting point of the plastic, thereby completing the rapid dissolution of solid materials and completing the welding.

The operating speed of this model is four times that of ordinary sewing machines, and the operation is simple. Suitable for making lace garments, ribbons, decorative products, handkerchiefs, tablecloths, curtains, bedspreads, pillowcases, duvet covers, tents, disposable surgical gowns, non-woven shopping bags, non-woven fabrics and other supplies.

Applicable materials: chemical fiber cloth, artificial leather, non-woven fabric, spray cotton, thermoplastic film, chemical plastic sheet, etc.

Configuration

Intelligent ultrasonic generator;20KHz ultrasonic transducer deviceSingle/dual motor speed control systemManual (or optional pneumatic) pattern lifting system;

Function

Trimming: Single-sided straight or curved cutting, and edge melting treatment, so that the edge is smooth, not rough, and without burrs;Stitching: Two or more layers of fabrics are stitched together, wireless needleless instead of sewing, and good welding strength;Hole-cutting: Cut out holes of various patterns, and do edge-melting treatment;Stripping: Single or multiple strips of the material can be opened and cut at the same time, and the edges should be melted without burrs;Forming: Cutting, stitching, and embossing at the same time, so that the product is formed at one time.

Features

There are various patterns of patterns, and designs can be provided according to customer needs;Super power output, with two levels of adjustable power, suitable for welding and cutting requirements of different materials and thicknesses;Built-in computer chip and multi-channel ultrasonic protection system to ensure the safe and stable operation of the host;The application of automatic frequency tracking system and ultrasonic soft start technology makes this machine powerful.

(1) Clothes lace, protective clothing, woven bags, (2) bed covers, (3) pillow cases, (4) car covers, (5) tents, (6) packing belts, (7) backpacks, travel belts, Hand straps, (8) curtains, (9) raincoats, windbreakers, snow coats, (10) toys, (11) gloves, (12) tablecloths, (13) chair covers, (14) duvet covers, (15) masks, (16) Hair accessories, (17) Accessories, (18) Umbrellas, (19) Lampshades, (20) Filters and other products