ABC Three Layer Co-Extrusion Plastic PE EVA Blown Extruder Film Blowing Machine

Basic Info

| Automation | Non-Automatic |

| Computerized | Non-Computerized |

| Machine Weight | About 6tons |

| Certification | CE |

| Screw Material | Double Alloy |

| Die Head | Rotary Head |

| Heater Material | Cast Aluminum |

| Motor | China / Siemens Is Optional |

| Inverter | China /Delta or Panasonic Is Optional |

| Electric Parts | Schneider /Panasonic |

| Temperature Control | Omron |

| Gear Box /Reducer | Shuguang /Hangzhou Weili |

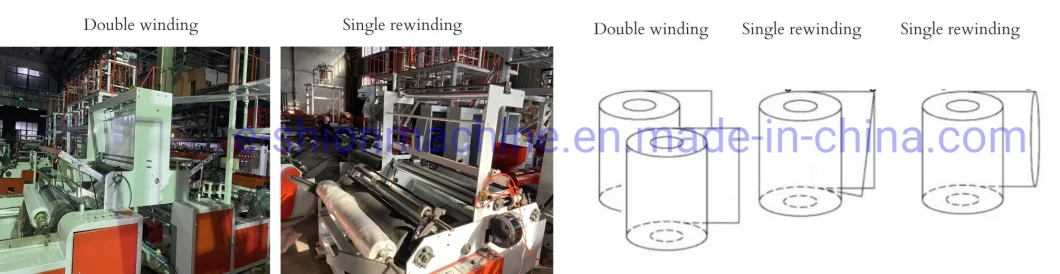

| Winder | Sing / Double |

| Air Ring | Double-Lip Air Ring |

| Transport Package | Plastic Film /Bubble Film |

| Trademark | E-SHION |

| Origin | China |

| HS Code | 8477309000 |

| Production Capacity | 100sets/Year |

Product Description

Product Description

The 3 layers film blowing line is composed in three extruders and auxiliary parts.It can be used for blowing with HDPE and LDPE,LLDPE, metallocene polyethylene, etc.through the extrusion die head to form three layer complex composite film.With greatly improving the physical properties of the films and an increase of strength, so that the films featured in good obstruct properties and air tightness.This thin film barrier properties, thermal insulation, waterproof,anti- frost, oxygen barrier, oil resistance and other excellent It can be widely used in heavy packaging, such as fruits, meat dishes, pickles, fresh milk, liquid beverages, etc.

Product Parameters

Main Technical Variables:

| Model | SJ-45×3/FM1000 | SJ-50×3/FM1200 | SJ-55×3/FM1500 | SJ-60×3/FM2000 | SJ-65×3/FM2500 |

| Screw diameter | Ф45mm | Ф50mm | Ф55mm | Ф60mm | Ф65mm |

| Screw ratio L/D | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 |

| Screw speed | 15-120r/min | 15-120r/min | 15-120r/min | 15-120r/min | 15-120r/min |

| Main motor power | 11kw×3 | 15kw×3 | 18.5kw×3 | 22kw×3 | 30kw×3 |

| Extrusion output(single) | 100kg/h | 120kg/h | 150kg/h | 180kg/h | 200kg/h |

| Range of die( THE DIE HEAD CAN BE SPECIAL ORDERED) | Ф200/ Ф250 | Ф200/ Ф250 | Ф250/ Ф300 | Ф500 | Ф600 |

| Single-sided thickness of film | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm | 0.03-0.10mm | 0.03-0.10mm |

| Max. Folding width of film | 1000mm | 1200mm | 1500mm | 2000mm | 2500mm |

| Electric total capacity | 76kw | 88kw | 102kw | 130kw | 156kw |

| Overall dimension | 6600×4100×5000mm | 6800×4300×6000mm | 7000×4800×6800mm | 7800×5300×8600mm | 8600×6200×9600mm |

| Weight of machine | 4.2T | 5.3T | 6.2T | 8.6T | 10.6T |

Certifications

FAQ

1.:Are you factory or trading company ?we are factory specialized in plastic machine for many years ,all of our engineer with more than 20 years experience .2. Where is your factory? How can i visit your company?our factory is located in Ruian city,zhejiang province, China.Its about 40 minutes from shanghai by plane(4 hours by train).we will pick you up on airport or station .welcome to visit our factory3 How long is your delivery time? On normal our delivery time is 30-45 days .if you need it ugently ,we can make your machine first.about 10 days4.:What's your warranty policy?18 month guarantee and whole life maintance , 5:What package do you use for the product?Be Coated with anti-corrosion oil, and covered with plastic film, wooden box package need extra cost . 6:Does your factory provide installation service?Our engineer can go to customer factory to installation . buyer should prepare materials used to testing the machine in advance and should be responsible for the cost of supplier's technician, including round air tickets, visa cost, accommodation and salary 100USD/Day per person since the day start out until the day arriving at factory.7:What are your terms of payment?We accept T/T, L/C. western union.8. How could we do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

Our Factory

Customer Feedback

Packaging & Shipping

Our Exhibition