1200mm Double Layer Co Extrusion Cast Stretch Film Machine

Basic Info

| Model NO. | CR-D1200 |

| Assembly Structure | Integral Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Don′t Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Material Feeder | Automatic Vacuum Loading |

| Screw Material | 38crmoaia Nitrogen Treatment |

| L:D | 30:1 |

| Driving Speed | Frequency Adjustment |

| Extrusion Die | T Die Like Clothes-Rack |

| Film Forming | Casting |

| Cooling | Internal Circulation |

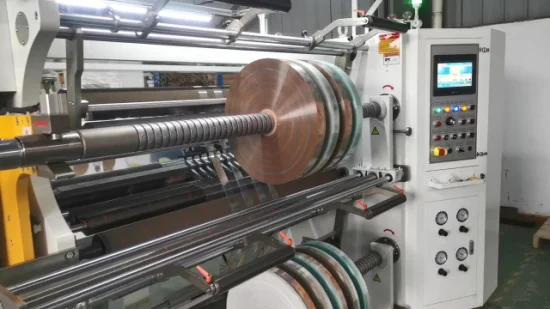

| Film Width Cutting | Slitting Online |

| Winder | Automatic Change Cutter |

| Cutter | Pneumatic Cutter Online |

| Edge Recycling Assistant | Trimming Recycling |

| Printer Assistant | Inkjet Printing Online |

| Transport Package | Film Wrapping by Container |

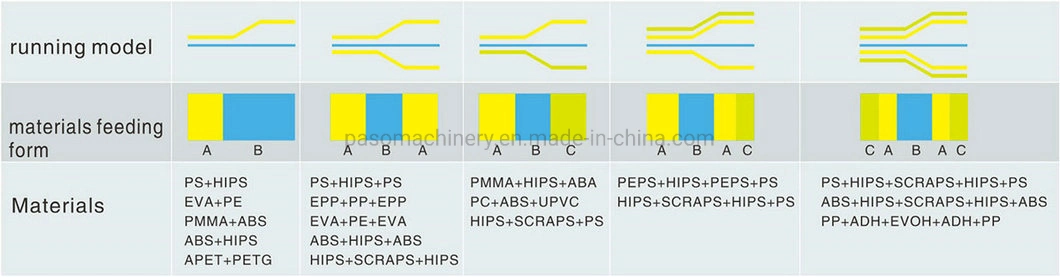

| Specification | Co extrusion layers |

| Trademark | PASO |

| Origin | China |

| Production Capacity | 180 Sets Per Year |

Product Description

PE Stretch film machine. The stretch machine uses LLDPE as main material and adopts several kinds of resins to manufacture the single/double-side self-sticky stretch wrapping film. The film has good tensile strength, anti-pricking ability and impact strength. Its good shrinking memory function and self-sticky can make goods integrity to prevent goods from loosening and collapsing during transportation and being polluted by dust. The transparency and tensile strength of this product can make the packaging beautiful, economical and practical. The film can be widely used in wrapping of palletized goods. Its a good substitute for hot shrinking packaging film during transportation

We have single layer, double layer, three layer stretch film making machine with different size, width in 500mm, 1000mm, 1500mm, The size can be customized; we also suplly PVC cling film machine if demand.

Feature:

1. Apply to kinds of resin grades to produce self-adhesive film, single-sided adhesive stretch film or double-sidesadhesive stretch film. The film has high tensile strength, puncture resistance and impact resistance;

2. The extrusion line adopts full frequency conversion control, the frequency conversion speed regulation runs stably, efficiently, and low energy consumption;

3. The product adopts a one-time molding process and has a special edge material trimming and recycling system.

4. Fully automatic mechanical roll changing, save labor force, running without stop, neat roll winding

Unit introduction:

This series unit is mainly used in producing the polyethylene plastic film for unidirectional stretch(stretching film, twines membrane)as well as fresh film.

Therefore it applies in building material,hardware fitting packing widely. The screw of unit adopts 38CRNOALA alloy steel.It manufactured by nitric and precise processing so that it is highly hardness and durable long time

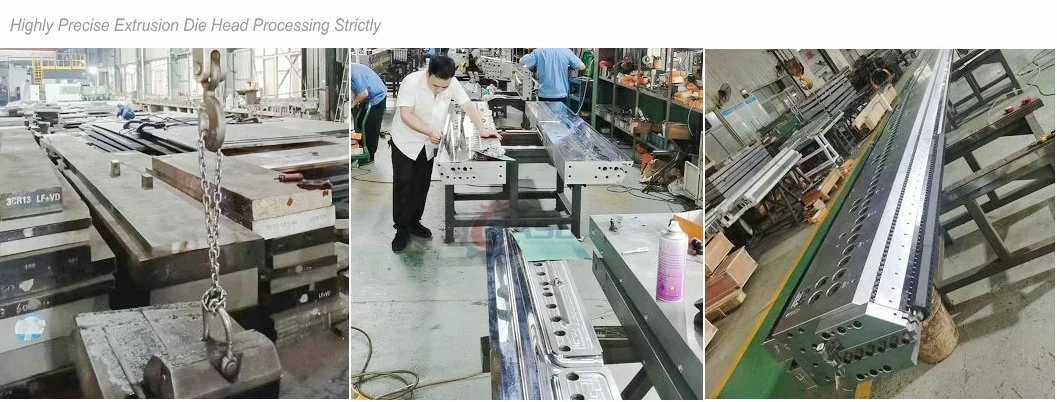

Temperature controls adopts advanced automatic control system and the T mold adopts the multi-spots adjustment. They could cause the film thickness to be evener.

The cooling system adopts the circulating water cool and it cooling effect is good .

the rollout installment adopts the friction type of rollout and has the cutting edge installment and side material rollout element by round-trip.This causes the film which rollout to be neater

| Item\Model | CR-S500 | CR-S1000 | CR-S1500 | CR-D500 | CR-D1000 | CR-D1500 |

| Screw diameter(mm) | φ65mm | φ75mm | φ85mm | φ55/55mm | φ55mm/75 | φ65mm/85 |

| L/D ratio of screw (L/D) | 30:01:00 | 32:01:00 | 32:01:00 | 30:01:00 | 32:01:00 | 32:01:00 |

| Material of Scerw & Barrel | 38CrMoALA | 38CrMoALA | 38CrMoALA | 38CrMoALA | 38CrMoALA | 38CrMoALA |

| Width of die head (mm) | 650 | 1250 | 1800 | 650 | 1250 | 1800 |

| Width of finished products(mm) | 200-500 | 200-1000 | 200-1500 | 200-500 | 200-1000 | 200-1500 |

| Thickness finished film (mm) | 0.015-0.05 | 0.015-0.05 | 0.015-0.05 | 0.015-0.05 | 0.015-0.05 | 0.015-0.05 |

| Structure of film layers | A | A | A | A/B | A/B | A/B |

| Max output (kg/h) | 40 | 100 | 150 | 60 | 150 | 250 |

| Linear speed (m/min) | 50-100 | 50-100 | 50-100 | 50-100 | 50-100 | 50-100 |

| Main motor power (kw) | 18.5 | 37 | 45 | 18.5x2 | 18.5-37 | 22-45 |

| Heating power(kw) | 15 | 18 | 30 | 30 | 50 | 72 |

| Tractiong motor(kw) | 2.2 | 2.2 | 4 | 2.2 | 2.2 | 4 |

| Total power (KW) | 45 | 90 | 150 | 80 | 140 | 190 |

| Weight (T)(About) | 3.2 | 4.5 | 5 | 4.5 | 5.5 | 7 |

| Overall size (L*W*H)m | 5.0*2.1*2.5 | 7.5*4*3.2 | 7.5*4.5*3.2 | 5.0*2.6*2.5 | 7.5*4.5*3.2 | 10*6.0*5.0 |

1.Packaging: wooden pallet or film wrapped (Fumigation wooden case usually)

2.Delivery time: 5-35/55 days after receiving deposit, depends on order and machine condition.

3.Exporting seaport: Ningbo port ; Shanghai port

4.Payment: we appreciate T/T 30% deposit, 70% balance paid before dispatching; Western Union;L/C acceptable if your goverment policy required

5.Trade terms: ExW,FOB,CFR,CIF,Door to Door, DDU, DDP,

Packaging & ShippingFAQ

1.Where is your factory Located

Our Factory Located in Ruian City ,Zhejiang Province ,China .

It is about 30minutes by air from Shanghai, around 5hours by train from Shanghai

2.What machines range we make & supply?

Our factory focus on manufacturing extrusion lines, complete bag production line, etc; OEM, ODM, with support of strong R&D team, we also help customer get best solutions for special equipments and plastic machinery;

3.How can we get satisfied machine in hand?

We will make test once machine in ready, to check every parts working condition and electrocircuit; will record relative photo and video for installation in your place.

3. What should we charge if we need engineer service in our country?

You should charge for the cost of our engineer's visa, air tickets, hotel, food, and also their salary (negotiable)

4. How long is your machine's warranty period?

All our machine have two years guarantee, starting from finished installation. we still keep service for whole life.

5. How could we do if the parts broken within warranty?

We would send the free replacement spare parts during the warranty date.